COMMERCIAL, PLANT & INDUSTRIAL SERVICES

Our Leeds based workshop facility has been servicing the UK since 1920

- Experienced time served staff

- Nationwide collection and delivery

- Fast turnaround

- Testing: pressure and flow rates.

- Repairs: leaks to the core and tanks

- Recondition service: full overhaul of the unit

- Recore: strip and reassemble with new core (upgrade if required)

- Remanufacture: complete design and fabrication of new radiator

- On site work (subject to feasibility)

If you need help right away or want to find out more,

call us free on

0800 002 9625

or email us at

info@northernradiators.co.uk

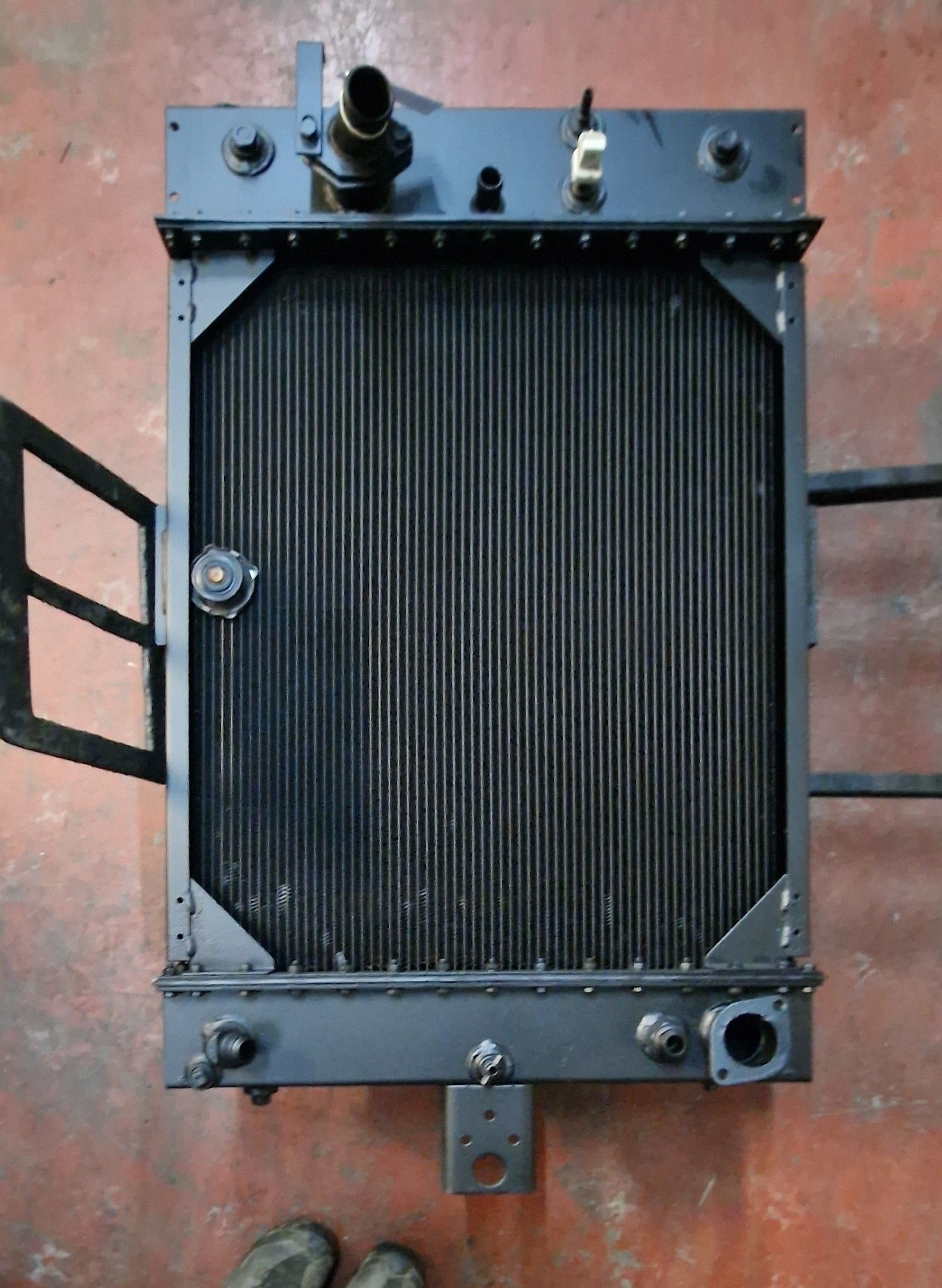

PLANT RADIATORS

Plant radiators come in many different types of construction and at Northern Radiators we offer the following for all plant vehicles

- Experienced time served staff

- Nationwide collection and delivery

- Fast turnaround

- Testing: pressure and flow rates

- Repairs: leaks to the core and tanks

- Recondition service: full overhaul of the unit

- Recore: strip and reassemble with new core (upgrade if required)

- Remanufacture: complete design and fabrication of new radiator

- On site work (subject to feasibility)

Many new units can be supplied, such as -

Caterpillar, Claas, Combilift, Compare, JCB, Johnston, Komatsu, Liebherr, Linde, Manitou, Perkins, Terex, Thwaites, Volvo Industrial

Written reports provided on request

INDUSTRIAL OIL COOLERS

Plant oil coolers are found on many different types of engines, manufactured in different ways, but they all have the same job: trying to cool oil, whether engine, hydraulic or transmission

If your plant vehicle is leaking oil, you run the risk of damaging the engine and needing an expensive repair job so don’t put off replacing your oil cooler, get a new one

We can repair or re-tube plant and heavy industrial oil coolers and can manufacture new units from pattern

Many new units can be supplied, such as -

Caterpillar, Atlas, Copco, Caterpillar, Compare, Dennis, Ingersoll Rand, Hitachi, JCB, Komatsu, Ransome, Thwaites

Written reports provided on request

INDUSTRIAL INTERCOOLERS

Intercoolers are found on many different types of engines and are manufactured in different ways, but they all have the same job – to cool the air that has been compressed by the turbo charger

Symptoms of a defective or leaking intercooler:

- Noticeable drop of the engine power effect. Caused by improper pressure in the turbo-charge system and improper ratio of oxygen in the fuel/air mixture

- Increased fuel consumption. Loss of oxygen causes an excessive intake of fuel to the mixture for the combustion process

- Unnatural smoke from the exhaust system. Provoked by a surplus of the fuel that cannot be combusted and is consequently emitted from the exhaust system

Northern Radiators supply many types of coolers, including many hard-to-find units. We can repair or re-tube plant and heavy industrial oil coolers and can manufacture new units from pattern.

Many new units can be supplied, such as Caterpillar, Daf, Foden, Komatsu, Scania, Volvo

BUS, TRUCK AND PLANT FUEL TANKS

Commercial tanks lead a hard life, external damage to the tank and filler neck is a common problem.

Inside. the tank can rot and rust away, and both problems are sure to make the tank leak. The last problem you need is the loss of expensive diesel or a large fine for leaking diesel on a public highway

We are experts when it comes to fuel tank repairs -we can repair plastic, steel or aluminium tanks.

All fuel tanks require chemical cleaning internally and externally to remove any trace of flammable fuel.

Small leaks and holes can be repaired by solder or welding.

Larger damage or leaks may require a new section of material welding to the tank

Should the tank be too badly corroded or rusty we can restore it with our Fuel Tank RENU system.

Fuel tanks usually suffer from a lot of wear and tear, and can end up punctured or scraped, which will often lead to corrosion and rust. The first thing people think of is to just replace it, but there is a more cost-effective and economically friendly way to deal with these damaged fuel tanks.

Fuel Tank RENU is a method in which old and corroded fuel tanks are cleaned and plastic coated.

The process used is both proven and patented. It can be cheaper and faster than simply purchasing a new fuel tan

HEADER TANKS

Most new vehicles have plastic header tanks that rarely fail, older vehicles have metal tanks that tend to leak with age

We can repair or fully recondition any metal header tank

If the header tank is contaminated, we descale and power clean with a mobilizing agent that removes all deposits and swarf

Then, a pressure test will reveal any leaks in the header tank, and after testing we will contact you with our findings and recommendations

- Cleaning. A chemical clean will remove any contamination that has settled in the tank

- Repairs. we can repair most header tanks as they are not normally rust damaged

- Recondition. Some header tanks will recondition. To recondition header tanks, we strip the tank down and clean all parts then bead blast before reassembly

- Remanufacture. We can manufactur new header tanks using an original as a template

FORKLIFT TRUCKS

Forklift radiators have a hard life working in warm and often dirty environments. We often see externally clogged up radiators due to debris getting trapped in the core, which almost always results in overheating

For customers who operate in industries such as wool mills and environmental waste, we can replace the standard core with a core designed to allow the contamination to pass through the core (not stick in it). Preventative maintenance is also a lot easier as the core can easily be pressure cleaned to remove contamination build up

Many new units can be supplied, such as

Caterpillar, Doosan, Hitachi, Hyster, Komatsu, Nissan, TCM, Toyota

INDUSTRIAL HEAT EXCHANGERS

Our time served staff have the expertise and skills to offer the following services:

- Testing - a pressure test will reveal any leaks, and a flow test will determine the extent of any internal blockage to the tubes. After testing we will contact you with our findings

- Cleaning -Internal blockages may be removed with a chemical clean. Badly blocked units will require a replacement. External blockage in the core can be removed with steam cleaning

- Repairs - We can repair many leaks, tubes, u-bends, and offer tube and gasket replacement. We have many repair techniques depending on the problem

- Recondition - Some units will recondition. The unit stripped down and all parts cleaned. Tubes will be unblocked, and tube joints resoldered, then the unit is reassembled and tested

- Remanufacture - We can remanufacture most heat exchangers, using the old unit as a pattern. In most cases we offer a price and turnaround that beats the original manufacturer

INDUSTRIAL HEATER CORES

Heaters, like car radiators, can choke up due to build up of deposits or dirt in the cooling system

Options for repair start from a chemical descale

If the heater is too badly blocked, we can replace the core with a high-performance equivalent

We also supply heater matrix for most makes and model of vehicle and if not on stock, we can usually get it for the next day.

As with radiators, we can repair, re-core or recondition more difficult to get heaters and can copy heaters that are made of aluminium.

TRAIN AND RAILROAD COOLERS

We have worked closely with the railroad industry and offer repairs, reconditions and re-cores to radiators, heaters, oil coolers, intercoolers and fuel tanks

For many years the German company Behr supplied sectional radiators to locomotive manufacturers across the world. Thousands of locomotives have been equipped with this type of copper/ brass cooler, with many of them still running.

We can supply the Mahle-Behr (OEM) specification sections either as a recore or unit complete with new brass tank, most with rapid production